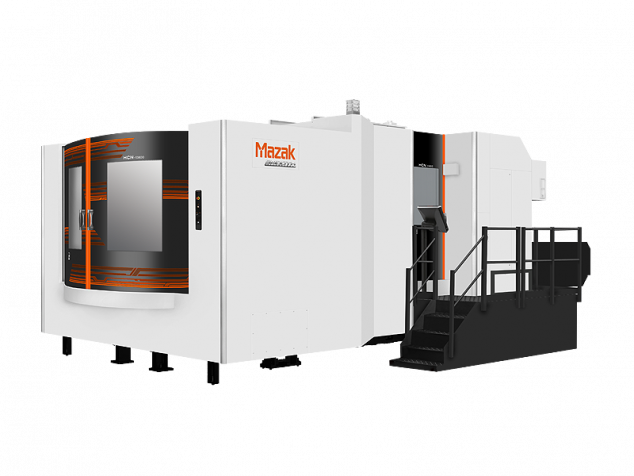

MAZAK NCH-10800

No.50 taper spindle ― High speed, high accuracy horizontal machining centers HCN-10800

·Spindle specifications to meet any production requirement

Standard : 10000 rpm

·Rigid machine construction for heavy duty machining as well as high accuracy finish machining

·Convenient tool setup thanks to tool magazine touch screen panel with intuitive operation

·Wide variety of optional equipment such as table specifications and tool magazine capacities are available

·MAZATROL SmoothG, the advanced CNC designed for ease of operation - standard equipment

MAZAK NCH-10800 Website

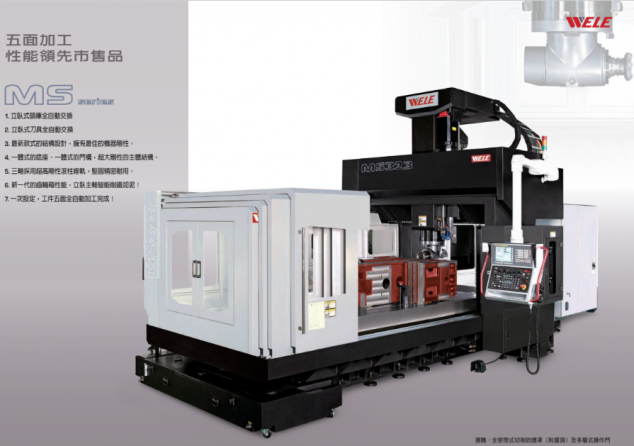

Bridge type Machining Center

Developed for high precision, heavy duty, and high performance on the smallest bridge range.

All axes are using ultra-heavy roller guideway.

Super wide operator door (full open). Easy to load and unload the workpiece.

Max. rapid feed up to 24m/min.

Have linear scale feedback system on X, Y,Z axes;

WELE SB-316 Website

AWEA LP-3021YZF

High Flexibility 5-Face Machining Capability Automatic Head Changer

And Vertical / Horizontal ATC System

The vertical / horizontal ATC system provides quick tool change with sensors and sequence scanning to ensure safety and reliability.

120-tool ATC system

AWEA LP-3021YZF Website

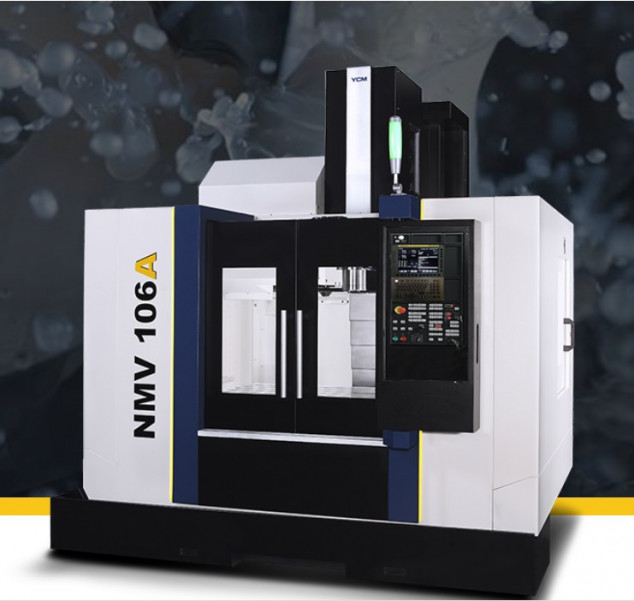

YCM NMV-106A 3+2

High Rigidity Structural Design

· Large delta machine column and base ensure the highest stability during high speed movement.

· 45 mm guideways on 3 axes have a super load capacity of up to 700 kg.

· X-axis equipped with 6 slide blocks increases rigidity by 50%, compared to previous model.

· Y-axis guideway span with optimal ratio

YCM NMV-106A Website